pecification Gate Valve - ASA Class 400/600

Suitable for : - Steam, Water and Oil

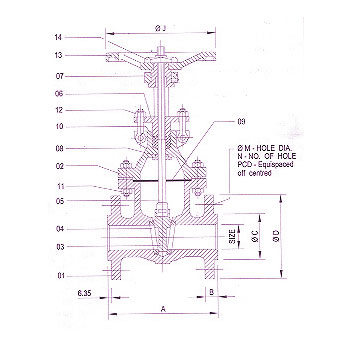

| No. | Description | Material | Qty. |

| 01 | Body | ASTM A 216 Gr. WCB | 1 |

| 02 | Bonnet | ASTM A 216 Gr. WCB | 1 |

| 03 | Wedge | AISI 410 ( 13% CR.) | 1 |

| 04 | Seat ring | AISI 410 ( 13% CR.) | 1 |

| 05 | Stem | AISI 410 ( 13% CR.) | 1 |

| 06 | Gland | Carbon Steel | 1 |

| 07 | Yoke Sleeve | NI - Resist | 1 |

| 08 | Bnnet Bush | AISI 410 | 1 |

| 09 | Gasket | Spiral wound metalic Gasket |

1 |

| 10 | Gland packing | Matalic Wire Reinforced Graphited Asbestos/ Grafoil |

-- |

| 11 | Bonnet Stud & Nut | ASTM A 193 Gr. B7 ASTM A 194 Gr. 2H |

-- |

| 12 | Eye Bolt & Nut | ASTM A 193 Gr. B7 ASTM A 194 Gr. 2H |

2 Set |

| 13 | Hand Wheel | Cast Iron | 1 |

| 14 | Hand Wheel Nut | Carbon Steel | 1 |

| Technical Data | |

| Manufacturing STD | API 600 / BS 1414 |

| Testing & Inspection STD | API 598 |

| Face to Face | as per ANSI B 16.10 |

| Shell wall thickness | ANSI B 16.34 |

| End connections | Flanged as per ANSI B 16.5 |

| Primary service reating & test pressure | ||||

| Class | Working press. | HYD. Test pressure | ||

| Body | Seat | Temp. | ||

| 400 | 400 PSIG | 1450 PSIG | 1060 PSIG | 800 °F |

| 600 | 600 PSIG | 2175 PSIG | 1600 PSIG | 800 °F |

| Air Test - Seat 80 PSIG ± 10 PSIG | ||||

| Class - 400 | ||||||||

| Size | A | B | øC | øD | øM | N | PCD | ø J |

| 40 | 242 | 22 | 73 | 156 | 22 | 4 | 114 | 250 |

| 50 | 291 | 25 | 92 | 165 | 19 | 8 | 127 | 305 |

| 65 | 331 | 29 | 105 | 191 | 22 | 8 | 149 | 305 |

| 80 | 357 | 32 | 127 | 210 | 22 | 8 | 168 | 405 |

| 100 | 407 | 35 | 157 | 254 | 25 | 8 | 200 | 405 |

| 125 | 456 | 38 | 186 | 279 | 25 | 8 | 235 | 490 |

| 150 | 496 | 41 | 216 | 318 | 25 | 12 | 270 | 490 |

| 200 | 598 | 48 | 270 | 381 | 29 | 12 | 330 | 610 |

| 250 | 674 | 54 | 324 | 445 | 32 | 16 | 387 | 675 |

| 300 | 763 | 57 | 381 | 521 | 35 | 16 | 451 | 825 |

| all dimension are in mm | ||||||||

| Class - 600 | ||||||||

| Size | A | B | øC | øD | øM | N | PCD | ø J |

| 40 | 242 | 22 | 73 | 156 | 22 | 4 | 114 | 250 |

| 50 | 292 | 25 | 92 | 165 | 19 | 8 | 127 | 250 |

| 65 | 331 | 29 | 105 | 191 | 22 | 8 | 149 | 405 |

| 80 | 357 | 32 | 127 | 210 | 22 | 8 | 168 | 405 |

| 100 | 433 | 38 | 157 | 273 | 25 | 8 | 216 | 490 |

| 125 | 509 | 45 | 186 | 330 | 29 | 8 | 267 | 490 |

| 150 | 560 | 48 | 216 | 356 | 29 | 12 | 292 | 610 |

| 200 | 659 | 56 | 270 | 419 | 32 | 12 | 349 | 675 |

| 250 | 788 | 64 | 324 | 508 | 35 | 16 | 432 | 825 |

| 300 | 839 | 67 | 381 | 559 | 35 | 16 | 489 | 825 |

| 350 | 890 | 70 | 413 | 603 | 38 | 20 | 527 | 825 |

| 400 | 990 | 76 | 470 | 686 | 41 | 20 | 603 | 1000 |

| all dimension are in mm | ||||||||

Note : Note: Due to constant up gradation, dimensions are subject to change by the manufacturer.