CHECK VALVES MANUFACTURER

UNIMAC Swing Check/Non-Return Valves are designed and manufactured as per API/BS/DIN STANDARD. Function of Check Valve is to prevent the reverse flow of fluid/gas/air in case of failure or sudden brake-down occurs in Piping Systems.

INDUSTRIAL BALL VALVES SUPPLIER

- The Sealing efficiency is a very critical aspect of Check Valves to safeguard pumping systems.

- UNIMAC check valves are designed to sustain backpressure and water hammering in piping systems.

- UNIMAC CHECK VALVES ARE AVAILALE IN SINGLE /DUAL PLATE DESIGN/WAFER/SWING TYPES.

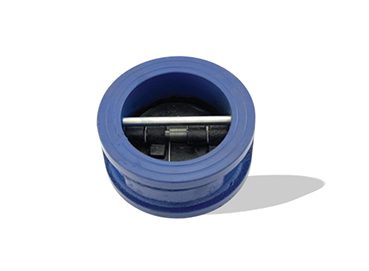

Unimac Disk check Valves (DCV)

DCV Check Valves

Installation:

Disc Check Valves must be fitted in accordance with the direction of flow arrow indicating correct fluid flow direction. When fitted with a spring they can be installed in any place. When supplied without a spring these must be fitted in a vertical flow line with the flow from bottom to top. The 'Cam' design of the body allows the various flanges types to be accommodated. The body is rotated to touch the flange joint bolts ensuring that a good joint is obtained.

* Also available screwed BSP/NPT or Socket weld Ends. Face to Face dimensions on request.

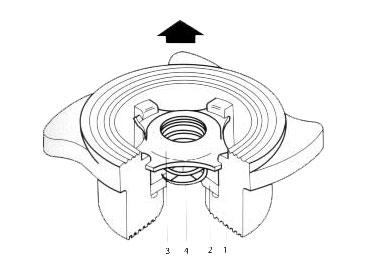

| No. | Part | Material | Grade |

| 1 | Body | Stainless Steel | ASTM A 351 Gr.CF8/ CF8M / 304 / 316 |

| 2 | Disc | Stainless Steel | 304/316 |

| 3 | Spring Retainer | Stainless Steel | 304/316 |

| 4 | Standard Spring | Stainless Steel | 304/316 |

| 5 | Heavy Duty Spring | Stainless Steel | 304/316 |

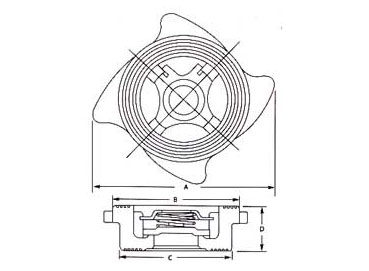

| DN | A | B | C | D | Wt / kg |

| 15 | 60 | 43 | 38 | 16 | 0.11 |

| 20 | 69.5 | 53 | 45 | 19 | 0.17 |

| 25 | 80.5 | 63 | 55 | 22 | 0.28 |

| 32 | 90.5 | 75 | 68 | 28 | 0.47 |

| 40 | 101 | 85 | 79 | 31.5 | 0.64 |

| 50 | 115 | 95 | 93 | 40 | 1.11 |

| 65 | 142 | 115 | 113 | 46 | 1.64 |

| 80 | 154 | 133 | 128 | 50 | 2.21 |

| 100 | 184 | 154 | 148 | 60 | 3.31 |

DCV Check Valves

- DN 15, 20, 25, 32, 40, 50, 65, 80 100

- Disc Check Valves can be fitted between BS:10 Table 'E' and 'H', BS:4504/DIN PN 6, 10, 16, 25, 40, JIS 5, 10, 16, 20, ASA 150, 300 flanges with the following exception.

- DN 40, 50, 80 and 100 - will not fit between JIS 5 flanges.

- DN 65 and 80 - will not fit between BS:10 Table 'E' flanges.

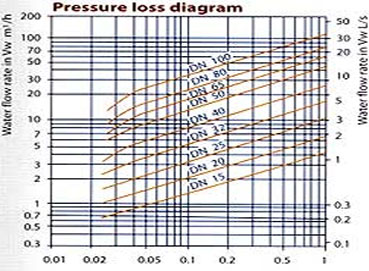

Opening Pressures in mbar

Differential pressures with zero flow

Flow direction

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 |

| 5 | 25 | 25 | 25 | 27 | 28 | 29 | 30 | 31 | 33 |

| 4 | 22.5 | 22.5 | 22.5 | 23.5 | 24.5 | 24.5 | 25 | 25.5 | 26.5 |

| 4 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

Where lowest opening pressures are required valves without springs can be installed in vertical pipes with bottom to top flow.

Without spring

| 5 | 2.5 | 2.5 | 2.5 | 3.5 | 4 | 4.5 | 5 | 5.5 | 6.5 |

Standard Of Shut Off

Standard Valves conform to DIN 3230 Part .BN 2. Soft seated versions give zero leakage provided a differential pressure exists.

Note - Disc Check Valves are not suitable for use where heavily pulsating flow exists, such as close to a compressor.

Standards

Designed and manufactured in accordance with BS 7438

Special Design Features

- ROBUST • LIGHT WEIGHT • COMPACT • ECONOMICAL

- DQuick open and close action.

- Can be mounted both vertical and horizontal position.

- Low pressure drop.

- High Cv value.

- Soft seated options available:

- VITON (for oil and gasses) - Temp.limits - 15ºC to 250ºC

- EPDM (for water) - Temp.limits - 50ºC to 150ºC

Limits

- Maximum body design PN 40

- PMO - Maximum operating pressure 40 bar g

- DTMO - Maximum operating temperature

- 300ºC with standard/heavy duty spring

- 400ºC without spring

- Maximum cold hydraulic test 60 bar g

- Minimum operating temperature - 500ºC

Application

- Delivery line of pumps.

- Steam and condensate systems.

- Vessels as foot valves.

- Filtration and ion-exchange process.

- Airline, water & effluent plants, corrosive liquids and gasses.

Download PDF File - Check Valves