FCS Gate Valves - ASA Class 800

| No. | Description | Material | Qty. |

| 01 | Body | Forge Steel ASTM A 105 | 1 |

| 02 | Bonnet | Forge Steel ASTM A 105 | 1 |

| 03 | Wedge | AISI 410 ( 13% CR.) | 1 |

| 04 | Seat ring | AISI 410 ( 13% CR.) | 1 |

| 05 | Stem | AISI 410 ( 13% CR.) | 2 |

| 06 | Gland Bush | AISI 410 ( 13% CR.) | 1 |

| 07 | Gland Flange | ASTM A 105 | 1 |

| 08 | Yoke Sleeve | NI - Resist | 1 |

| 09 | Bonnet Gasket | Spiral wound s.s. 304 with CAF | 1 |

| 10 | Gland packing | S.S. Metal wire braided Asbestos | -- |

| 11 | Bonnet Stud & Nut | ASTM A 193 Gr. B7/ ASTM A 194 Gr. 2H | 4 Set |

| 12 | Eye Bolt & Nut | Forged C.S. | 2 Set |

| 13 | Screw & Washer | M. S. Galvanised | 2 Set |

| 14 | Hand Wheel | Cast Iron / C.S. | 1 |

| 15 | Hand Wheel Nut | Carbon Steel | 1 |

| Technical Data | |

| Manufacturing STD | API 602 |

| Testing & Inspection STD | API 598 |

| Socket weld and Threaded to | As per ANSI B 16.10/ ANSI B 1.20.1 |

| Flanged to | ANSI B 16.34 |

| Fnaned to Flange Distance | ANSI B 16.10 |

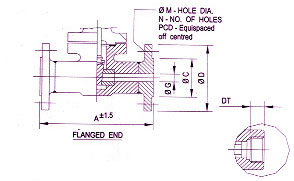

| Class - 300 | |||||||

| Size | A | ø C | ø D | ø G | ø M | N | PCD |

| 15 | 139 | 35 | 95 | 14 | 16 | 4 | 66.5 |

| 20 | 151 | 43 | 118 | 16 | 19 | 4 | 82.5 |

| 25 | 164 | 51 | 124 | 17.5 | 19 | 4 | 89.0 |

| 40 | 190 | 73 | 155 | 21.0 | 19 | 4 | 114.0 |

| 50 | 215 | 92 | 165 | 22.0 | 22 | 8 | 127.0 |

| Screwed / Socket Weld Class - 800 | |||||||||

| Size | A | B | ø E | ø F | ø G | H | H1 | DT | øJ |

| 15 | 86 | 10 | 13 | 22.0 | 9.5 | 154 | 174 | 13 | 94 |

| 20 | 91 | 13 | 15 | 27.5 | 14.0 | 160 | 185 | 13 | 94 |

| 25 | 104 | 13 | 22 | 34.0 | 18.0 | 168 | 198 | 15 | 98 |

| 40 | 127 | 15 | 36 | 48.6 | 32.0 | 231 | 274 | 25 | 142 |

| 50 | 143 | 16 | 45 | 61.0 | 42.0 | 242 | 287 | 25 | 142 |

| Class - 150 | |||||||

| Size | A | ø C | ø D | ø G | ø M | N | PCD |

| 15 | 107 | 35 | 89 | 11 | 16 | 4 | 60.4 |

| 20 | 119 | 43 | 98 | 13 | 16 | 4 | 70.0 |

| 25 | 126 | 51 | 108 | 14 | 16 | 4 | 79.0 |

| 40 | 164 | 73 | 127 | 14 | 16 | 4 | 98.5 |

| 50 | 177 | 92 | 152 | 16 | 19 | 4 | 120.6 |

| Test Pressure | |

| Body | Seat |

| 3000 PSIG | 2000 PSIG |

| Air test of seat at 100 PSIG | |

| all dimesion are in mm | |

Note : Due to constant up gradation, dimensions are subject to change by the manufacturer.